Basic Transfer Point Example

The most common transfer chute is used to transfer material off of one conveyor and onto a second. In this example you will have one load point, two conveyor belts and the chute work. Some typical scenarios where you would run this type of model include:

- The transfer chute cannot handle the tonnage we are trying to get through it.

- We increasing the tonnage through the chute by increasing the belt speeds. What will be the impact on the chute? Can it handle the higher tonnage?

- We are getting a lot of dust. Can we do something with the chute design to help reduce this?

- We are wearing out or damaging the receiving belt. What can we do to improve the situation?

You start off by drawing the chute and belting in 3 dimensions in AutoCAD using 3D faces. Several of our customers have started off saying "Our designers know AutoCAD but don't work in 3D." Don't worry we have found that most proficient AutoCAD users are able to draw proficiently in 3D in a matter of hours. We have also found that many of the designers end up preferring to design in 3D, as they should, before doing the construction drawings in 2D.

In drawing the incoming belt surfaces take special note to the belt transition distance and location, height, of the last idler set before the discharge pulley. This detail is critical to correctly modeling the trajectory of the material as it leaves the discharge pulley.

The dxf drawings of our example chute are included here:

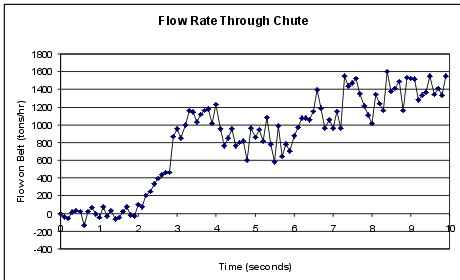

This example is run with a material with a density of 1.65 t/m^3 (75 lb/ft^3), a flow rate of 2000 tph (1800 stph), a size distribution from 75mm to 100mm (3in to 4in) diameter and belt speeds of 3.5 m/s (600 ft/min). These parameters are entered into the Chute maven program.

The 10 seconds of simulation time are run, taking approximately 4 hrs on a Pentium M computer, and reaching 5000 particles in the simulation. An AVI of the material flow is shown here:

Click to view movie in mpeg4 AVI format.

From the data available in the program we can plot the tonnage exiting the simulation on the second belt and plot in MS Excel.